Advantage to Wet Blasting 3D Printed Parts

Additive manufacturing (AM) continues to disrupt the traditional manufacturing paradigm, and every day secures a more robust foothold as a production technology. But AM has its issues, and one of the big ones is post-processing. Colin Spellacy, Head of Sales. Rösler UK/AM Solutions, writes that wet blasting may be the solution to this problem.

As is now well-known and accepted, AM is important as it facilitates the creation of geometrically complex parts and components, reduces waste, and allows for the creation of lighter structures with an obvious importance in the automotive, aerospace, and medical sectors.

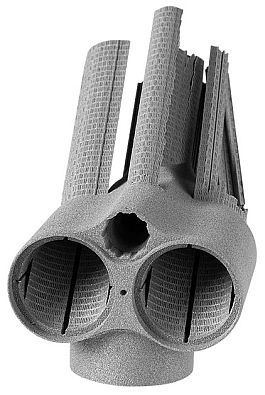

Wet blasting cleans 3D printed components by removing residual powder and reduces their initial high surface roughness.

But AM is not perfect, and one area where significant issues reside is in the surface finish of AM parts as they come out of the build chamber or off the build plate. AM produced parts require primary post-processing processes to remove powder or physical supports.

But even then, AM parts are characterized by relatively poor look and feel, layer steps often being obvious, and surface roughness often being significantly high, which can affect aesthetics as well as functional performance. This means that in most instances, they require secondary post-processing to enhance surface form and finish.

With a significant part of the cost of a finished end-use AM part being the cost of post processing, the fight is on to develop efficient, repeatable, and automated AM post processing technologies. Many companies are working on and researching new bespoke AM post-processes, sometimes with impressive results, but usually restricted in usefulness to particular materials or geometries, and almost all being highly priced and over-engineered.

VIDEO: S1Wet -- The versatile wet blast solution for cleaning and surface finishing

Because of this, an increasing number of traditional industry finishing processes are being refined and positioned for the post-processing of additively manufactured plastic and metal parts. A number of mass finishing technologies are already used such as vibratory finishing, tumble finishing, and shot blasting. Shot peening and chemical smoothing technologies also maintain a foothold.

In this article, however, we will take a look at a finishing / post-processing solution that is largely neglected when looking at AM parts, and that is wet blasting. Wet blasting is a clean, reliable, repeatable, and accurate process which creates parts with a consistently superior surface finish than alternative processes, and which is ideal for parts made using direct metal laser sintering (DMLS) and selective laser sintering (SLS).

What is Wet Blasting?

From the family of shot blasting post-processing technologies, wet blasting is what it is called when water and abrasives media work together, and it is particularly well suited for the finishing of delicate, precision-produced parts.

Wet blasting technology makes parts more homogeneous and therefore better prepared for effective mass finishing.

The process is characterized as being dust free, can use very fine abrasives, uses very low volumes of abrasives due to the protective water layer, and minimizes the risk of embedding (especially for soft metals). It also produces what is perhaps the most important AM post-processed part characteristic, superior surface finish.

Wet blasting typically sees a mix of between 10-40% abrasive media to water. The slurry is pumped to the blast gun and then accelerated to a high velocity using compressed air through a blast gun nozzle that is directed at the part. The blast media impact on the work piece creates the desired effect, be that cleaning, surface smoothing, coating preparation, cosmetic surface texturing, or peening.

Wet blasting machines can easily be integrated into an automated production line or used as an isolated stand-alone technology.

Advantages of Wet Blasting

Wet blasting has benefits for the characteristics of the work piece itself, but also for the processing environment. The over-riding advantage is it gentleness, but also the process produces no dust, which prevents electro-static issues and therefore removes the need to consider ATEX regulations concerning explosive atmospheres.

For post processing of 3D printed components, wet blasting can remove powder and support structures while smoothing the surface.

There is also no media impingement using wet blasting, an ever-present problem with dry blasting where media particles can embed in the work piece surface compromising surface integrity.

Dry blasting generates significant heat during post processing which when combined with high impact energy of the media on the work piece can lead to warping and bending of delicate parts. Wet blasting by contrast is a cooler gentler process that is especially suited to the post processing of fragile thin-walled parts and components.

When it comes to powder removal on AM parts (even in hard-to-reach internal channels and features) wet blasting immediately washes away anything that is adhering to the work piece.

Wet blasting machines can be utilized as stand-alone systems, or they can be easily integrated into your existing manufacturing line.

In terms of surface finish, wet blasting promotes smoother finishes while being more precise, consistent, and repeatable. Finishes are fine and uniform, with low surface roughness of 100µm Ra being easily attainable. From a cosmetic surface finish perspective wet blasting creates a smooth matte effect, and the less abrasive nature of process and lack of warping and bending allows for the attainment of much tighter tolerances.

A key advantage is the versatility of the process, as blast intensities and media concentrations can be easily adjusted to accommodate different materials and the different geometric structures to eliminate damage to part form and function.

Wet Blasting for AM

Wet blasting is an essential technology for various AM post processing tasks.

Wet blasting cleans the 3D printed components by removing residual powder and significantly reduces their initial high surface roughness. It is capable of de-powdering and providing general surface cleaning and initial surface smoothing from Ra 25 µm to 1--1.5 µm. The technology makes parts more homogeneous and therefore better prepared for effective mass finishing, which also takes less time once a part has been wet blasted.

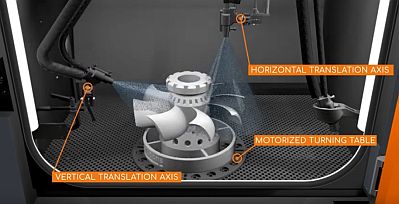

Equipped with numerous accessories, the S1 Wet System can be perfectly adapted to your cleaning, surface homogenization and/or smoothing requirements.

On metal AM parts the loosely sintered grains on corners are effectively removed. The wet process eliminates the worry about residual powder containment or sparking during the blasting process.

Wet blasting can be applied to and provide numerous finishes to metal and non-metal parts alike. Different media and different blast intensity customizes the surface finish achieved. In addition, many AM parts require coating or painting post-build, and wet blasting creates what is called a "wet out" surface that allows the optimal adhesion of paints or coatings.

Changing media amount and blast intensity allows the effective cleaning and de-powdering of a variety of plastic and metal AM parts with wet blasting. Often, AM parts have difficult to reach internal channels and complex geometries which are not well served by dry blasting technologies, but which are easily and demonstrably cleaned and completely de-powdered using wet blasting.

Want more information? Click below.

Rate this article

View our terms of use and privacy policy ::m::